Honeywell 5800C2W Installation Manual - Original

Related Products

Related Categories

Document Transcript

Document ID: 800-15422 . Dated: 9/13 Rev. B

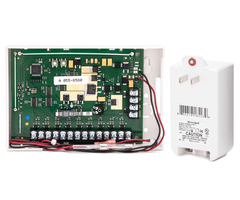

5800C2W / 5800C2WCN Convert to Wireless Module – Installation Instructions

GENERAL INFORMATION

The Honeywell 5800C2W Convert to Wireless Module (referred to as the 5800C2W, module, or 5800C2WCN in Canada) enables retrofitting existing security systems by; converting their wired sensors to Honeywell’s 5800 series wireless technology, and replacing the existing control panel with a LYNX Touch or LYNX Plus series control. The 5800C2W also works with residential VISTA control panels equipped with a wireless RF receiver and keypad. IMPORTANT: This product is NOT for use with fire / heat sensors. SPECIFICATIONS Dimensions Length 7.0 in (178mm) Width 4.5 in. (114mm) Depth 1.5 in. (38mm) Double stick tape and screws included. +14 to +140°F (– 10 to +60°C) 95% RH Max. Up to 300ft. (91 meters) Supplied by plug-in transformer 15.5VDC (± 5%) @ 1A P/N: 300-07052, or 300-07102 Canada Input Zones (9 hardwired) Auxiliary Output (12VAUX) LED Status Indicators Battery Backup Use 12V, 4Ah battery such as Honeywell 467, Yuasa NP4-12, Casil CA1240 or equivalent. Provides 4 hours of backup. Battery is to be located in the existing control panel. DO NOT use batteries of larger capacity. Activated when the cover is removed. • low battery • backup battery power • each enrolled zone transmits a supervisory message every 72 minutes • AC loss is reported as low battery (See LED descriptions on back page.) • input power • backup power • wireless transmission

Tamper Detection 5800C2W Supervision

Mounting Hardware Operating Temperature Humidity Transmission Range Operating Voltage

(The input power indicator is viewable through the enclosure cover.) All zones that are used must have an EOL resistor. (Refer to the back page for detailed information.) Provides 11.2VDC ±15% @ 100mA to supply PIR motion, or glassbreak sensors.

1

Mount and wire the module

Mounting and Wiring: Note: This product must be installed in accordance with ANSI/NFPA 70, National Electrical Code. 1. Refer to the wiring diagram on the back. 2. Select a mounting position for the module. In most installations locating the module close to the existing control panel is ideal. Note: If needed, the 5800C2W can be located remotely by extending the existing sensor wires. If needed, you may cut and splice (observing good workmanship) the battery wires and extend their length up to 0.9 meters (3ft) using 22 AWG wire, minimum. Ensure the integral battery cable fuse is positioned inside the control panel enclosure. 3. Mount “Tamper Magnet” to enclosure cover. 4. Attach using the supplied double stick tape (and screws if desired). 5. Ensure the wiring is complete. Use cable ties as necessary to secure wiring. Plug the power transformer into an un-switched outlet and secure with screw. Then attach the backup battery wires.

Guidelines: • Since the existing control panel is being replaced, its security functions will be performed by the new LYNX or VISTA control panel. • The existing control panel can remain for the purpose of housing the backup battery. Further, the existing control panel can be powered down and the transformer unplugged. • The 5800C2W module will charge the battery. This is also a good time to replace the existing battery if needed. • At the existing control panel, tag and remove the sensor wires as they will now go to the 5800C2W. Up to nine [9] hardwired zones can be handled by each 5800C2W module. • DO NOT mount inside the control panel or other metal enclosure. • The integral battery cable fuse MUST be positioned inside the control panel enclosure. The fuse is not replaceable. • Before mounting permanently, conduct Go/No Go tests (see control’s instructions) to verify adequate signal strength, relocate if necessary.

2

Calibrate the module zones

3. DONE. The 5800C2W is calibrated and ready to enroll in the control panel. Note: If the 5800C2W loses both AC and battery backup power, the zone calibration data is retained.

Calibration: The calibration process enables the 5800C2W to learn what zones will be active and what value EOL resistors are used. Unused zones that are open WILL NOT be recognized and reported. 1. Ensure all zones are connected and not tripped. 2. On the 5800C2W, click the top left button (SW2). Indicator LED #1 will flash Red for 1/2 second, then turn steady Green.

3

Enroll the module in the control panel

Method 1: 1. Refer to the control panel’s guide and set it to “Zone Programming” mode. 2. Enroll the first zone as an "RF" type (supervised RF) device in the control panel.

Enrollment: As a wireless device, each 5800C2W has a unique 7-digit serial number to enable the control panel to recognize it. Further, since the 5800C2W has nine zones each zone is automatically assigned the next sequential serial number. Remember, unused zones are not reported or transmitted to the control panel. For example, below all zones except #6 are used: Item zone 1 zone 2 zone 3 zone 4 zone 5 Serial # xxx-xxx1 xxx-xxx2 xxx-xxx3 xxx-xxx4 xxx-xxx5 Item zone 6 (if not used) zone 7 zone 8 zone 9 Serial # none xxx-xxx7 xxx-xxx8 xxx-xxx9

3. Trip the zone (LED #1 flashes Green to indicate the information has been sent) and wait for the keypad to beep (about 2 seconds), then trip zone again. Confirm the correct serial number has been enrolled. Repeat for each zone used. Method 2: 1. Locate the unique 7-digit serial number for the 5800C2W module. This is located on the carton and on the module’s circuit board. 2. For each zone used, increment (in order) the 7-digit serial number to determine the serial number for each zone. Refer to the example table to the left. Note: The next step can also be done using Honeywell’s Compass software. 3. Refer to the control panel’s guide and manually program the 5800C2W module, followed by each of its zones. • All zones are Loop 1. • The 5800C2W tamper switch is assigned Loop 4 for the lowest numbered zone used.

• All zones are Loop 1. • The 5800C2W tamper switch is assigned as Loop 4 for the lowest numbered zone used. Enrolling the 5800C2W into the control panel is similar to any 5800 series wireless device. There are two methods that can be used.

LED #1 #2

Function Note: LEDs are shown as they appear on the circuit board. Red (blinking) – Module needs calibrating. Green – Module is calibrated. Green – DC power (15.5VDC, ± 5%) from the plug-in transformer is present. Red – DC power is NOT present. (Viewable through the enclosure cover.) Yellow – Low battery or No battery. When the battery voltage drops to 11.2VDC, a low battery message is sent to the control panel and LED 3 turns yellow. When the battery voltage drops to 10.0VDC, the battery is disconnected. The battery will not connect again until AC is restored. Green (blinking) – RF signal transmission.

#3

#4 Zone Calibration button. Not Used.

To backup battery located in existing control panel.

OBSERVE POLARITY.

Zone 1 of 9 shown wired.

Provides 11.2VDC ±15% @ 100mA to supply PIR motion, or glassbreak sensors. (Minimum voltage is 10.5VDC.)

NOTES: • All zones that are used MUST have an EOL resistor. • If the existing installation zones have EOL resistors (from 1k to 10k ohms) they may remain.

• For a NC loop without an EOL resistor, you must add one in series with the loop. • For a NO loop without an EOL resistor, you must add one in parallel (across) the

loop. Preferably it should be located at the end of the loop furthest away from the control panel.

• EOL resistor values must be from 1k to 10k

ohms. IMPORTANT: The first battery test occurs 1 hour after power up. To quickly verify a good backup battery, unplug and then plug back in the power supply; the system will perform a battery test within 1 minute.

FEDERAL COMMUNICATIONS COMMISSION STATEMENTS The user shall not make any changes or modifications to the equipment unless authorized by the Installation Instructions or User's Manual. Unauthorized changes or modifications could void the user's authority to operate the equipment. CLASS B DIGITAL DEVICE STATEMENT This equipment has been tested to FCC requirements and has been found acceptable for use. The FCC requires the following statement for your information: This equipment generates and uses radio frequency energy and if not installed and used properly, that is, in strict accordance with the manufacturer's instructions, may cause interference to radio and television reception. It has been type tested and found to comply with the limits for a Class B computing device in accordance with the specifications in Part 15 of FCC Rules, which are designed to provide reasonable protection against such interference in a residential installation. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures: • • • • • • If using an indoor antenna, have a quality outdoor antenna installed. Reorient the receiving antenna until interference is reduced or eliminated. Move the radio or television receiver away from the receiver/control. Move the antenna leads away from any wire runs to the receiver/control. Plug the receiver/control into a different outlet so that it and the radio or television receiver are on different branch circuits. Consult the dealer or an experienced radio/TV technician for help.

INDUSTRY CANADA CLASS B STATEMENT This Class B digital apparatus complies with Canadian ICES-003. Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada. FCC / IC STATEMENT This device complies with Part 15 of the FCC Rules, and RSS210 of Industry Canada. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) This device must accept any interference received, including interference that may cause undesired operation. Cet appareil est conforme à la partie 15 des règles de la FCC & de RSS 210 des Industries Canada. Son fonctionnement est soumis aux conditions suivantes: (1) Cet appareil ne doit pas causer d’interférences nuisibles. (2) Cet appareil doit accepter toute interférence reçue y compris les interférences causant une réception indésirable.

WARRANTY Go to: http://www.security.honeywell.com/hsc/resources/wa/ DOCUMENTATION AND ONLINE SUPPORT Go to: http://www.security.honeywell.com/hsc/resources/MyWebTech/ 2 Corporate Center Drive, Suite 100 P.O. Box 9040, Melville, NY 11747 Copyright 2013 Honeywell International Inc. www.honeywell.com/security

Ê800-15422}Š

800-15422 9/13 Rev. B

- Uploaded